Expand Your Knowledge With Our Technical Training

Whether you need to build foundational understanding of fluid and sampling systems or you want to stay up to date on the latest technologies and best practices, Swagelok offers robust training. Swagelok training programs provide a range of valuable and practical tools for meeting day-to-day challenges related to fluid systems and sampling systems. Our trainers can provide you, your associates, installers, and maintenance vendors with a wide range of training to minimize installation and maintenance errors, and ensure your system maintains its reliability.

Customize Your Training Experience

Our Essentials training courses can be combined to get the most out of your training experience. Our individual course offerings are a day in length, so you could combine our Tube Fitting Installation Essentials with our Medium/High Pressure Cone and Threads Essentials Class to make it two consecutive days of training — the decision is yours! Check out our training offerings below:

Training Courses

Swagelok Tube Fitting Installation Essentials Class

Our Tube Fitting Installation Class is designed to teach students foundational fitting knowledge that will minimize risk of leakage and ensure their systems integrity.

Swagelok Tube Fitting Installation Inspection Class

This course will cover the proper installation techniques to mitigate and minimize risk of leakage.

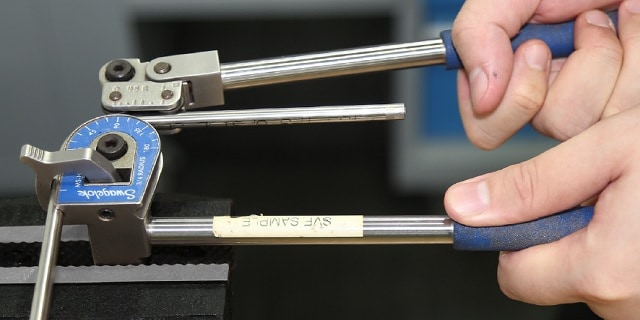

Swagelok Tube Bending Essentials Class

Gain foundational knowledge on bending techniques, tube preparation, bend terminology and correct measuring of tube and bending effects.

Swagelok Medium/High Pressure Cone and Thread Essentials Class

Acquire the fundamental understanding of cone and thread preparation and installation.

Swagelok Hose Essentials Class

Learn the fundamentals of fluid system hose like terminology, end connection attachment methods and selection considerations.

M200 Orbital Welding Class

Gain a basic understanding of orbital welding principles, processes, equipment, weld variables, weld quality, weld schedules and weld fixture set up.

Process Analyzer Sampling System Class

This course will help you understand sampling systems while designing and building an optimized system that delivers timely, accurate results.

Process Analyzer Sampling System (PASS Subsystems) Class

This course will help you understand how each subsystem impacts analyzer results.